Advantages and disadvantages of overlapping curtains

Passive fire protection is a fundamental pillar in building safety, ensuring the compartmentalization of fire and smoke to prevent their spread to other areas. Within these solutions, fire curtains play an essential role, and within this category, we find overlapping curtains.

Their design allows for the installation of compartmentalization barriers without structural interruptions, making it easier to protect large areas without the need for rigid divisions. But how do they really work, and in what cases is their use recommended?

What will you learn in this post?

-

You will learn what an overlapping curtain is.

-

You will discover the characteristics and advantages of overlapping fire curtains.

-

You will understand when their installation is recommended.

What are overlapping curtains?

Overlapping curtains are a type of fire protection textile barrier designed for large-scale closures. Their operation is based on the overlapping of multiple curtain modules, which, when layered, ensure continuous fire-resistant coverage without length limitations.

This type of solution is used in spaces where single-piece curtains are not feasible, whether due to logistical, structural, or architectural design restrictions. Their installation is common in industrial warehouses, shopping centers, airports, and large infrastructures, where effective compartmentalization is vital for evacuation and fire containment.

Fire curtain modular MFBD E-120

Product DetailsMain features of overlapping curtains

Overlapping curtains not only allow coverage of large dimensions but also present a series of technical characteristics that directly influence their effectiveness and application. Below, we detail the key aspects that define them.

Modular configuration

Overlapping curtains are composed of multiple technical fabric modules, designed to overlap with each other to create a continuous fire barrier. This configuration facilitates their adaptation to different architectural sizes and shapes without compromising fire resistance.

The modular design allows for efficient manufacturing and assembly, as predefined modules can easily be adjusted to the required dimensions of each project. Moreover, the overlapping system reduces the need to manufacture a single large piece, improving transportation and installation.

On the other hand, their segmented structure makes maintenance and replacement tasks easier, as only the affected modules need to be replaced without changing the entire curtain.

Thanks to this configuration, overlapping curtains do not require intermediate structural elements, allowing for open and functional spaces without compromising safety or fire compartmentalization.

Dimensional flexibility

Unlike other fire protection solutions, overlapping curtains have no width limitations, allowing them to cover large openings without interruptions. This is especially useful in infrastructures where the aim is to maintain open spaces, such as airports, train stations, or shopping centers.

Additionally, their installation system allows precise adjustments based on the requirements of each project, adapting to the building’s structural conditions without the need for significant modifications. Their adaptability is one of their greatest advantages, as it enables their integration into different environments without altering the layout, space usage, or design.

Precision in installation

One of the most critical factors in installing overlapping curtains is the precision of the overlap adjustment. The overlap length of the fabrics is not fixed but must be calculated based on the curtain height, following the guidelines of standard EN 15269-11.

The design and testing of these systems pose a great challenge for manufacturers. Depending on the chosen system configuration, two overlaps may need to be implemented to justify modulations of more than two rollers, adding complexity and increasing the risk of failure.

It is important to note that both design and installation work must be carried out carefully, considering different aspects to achieve an effective solution. The overlap measurements must be precise with minimal deviations. A thorough verification should be carried out after installation to confirm the correct operation in case of contingency. The fabric height should be checked to ensure no excess fabric and that it meets the tolerances specified by the manufacturer.

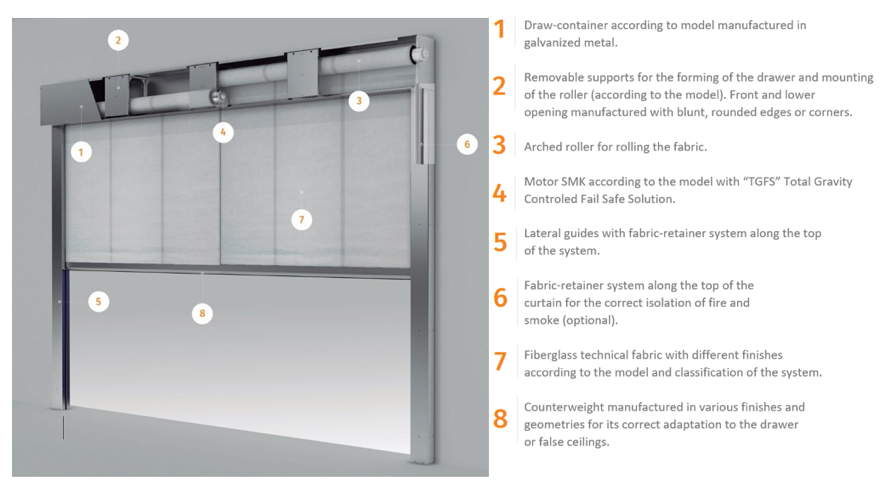

It is a system comprised of several rollers that, by superimposing their position, allow the fabrics to be overlapped according to the needs required for their correct operation and compliance with current regulations.

When to choose an overlapping curtain?

The choice of an overlapping curtain depends on the specific needs of the project, as well as the structural conditions of the space. This type of solution is recommended in the following cases:

-

When the dimensions of the opening to be protected exceed the capacity of a single-piece curtain.

-

When a solution is sought without intermediate structures that interfere with the functionality or design of the space.

-

When large areas need to be compartmentalized without affecting mobility or the use of space in normal conditions.

In many cases, if space allows, it may be advisable to opt for single roller curtains, as their installation and maintenance are generally easier. However, when the dimensions or logistical conditions do not allow this option, overlapping curtains are the best alternative.

At Tecnitex, we understand the importance of offering products that meet safety and quality standards in the fire protection sector. That is why we offer fire curtains and smoke control barriers that adapt to different spaces. If you need advice on which type of curtain is the best option for your project, contact us, and we will help you find the most suitable solution.