What is BIM and its contribution to project management in the construction sector

In this article, we dive into the concept of BIM and focus on its contribution to the construction industry throughout the entire process, which allows us to facilitate the management of information about our products in a project. Let’s get started!

What will you learn in this article?

- What is BIM

- What does BIM bring to the construction industry

- What do Tecnitex BIM objects bring to our clients

⇢ What is BIM?

BIM (Building Information Modeling) is a collaborative methodology that involves creating a shared data model that allows the exchange of information between all agents involved in a construction project, across all disciplines (Architecture, Structures, and MEP), and at all stages of the project, from design to asset maintenance.

⇢ What does BIM bring to the construction industry?

The BIM methodology has changed the way buildings are designed, constructed, and maintained. Having a digital model makes it easier to manage the data of each element in the project. The 3D model helps anticipate potential problems that could arise during construction, such as detecting clashes, having more control over scheduling, reducing cost overruns, managing required maintenance during the building’s lifespan, or reducing energy consumption.

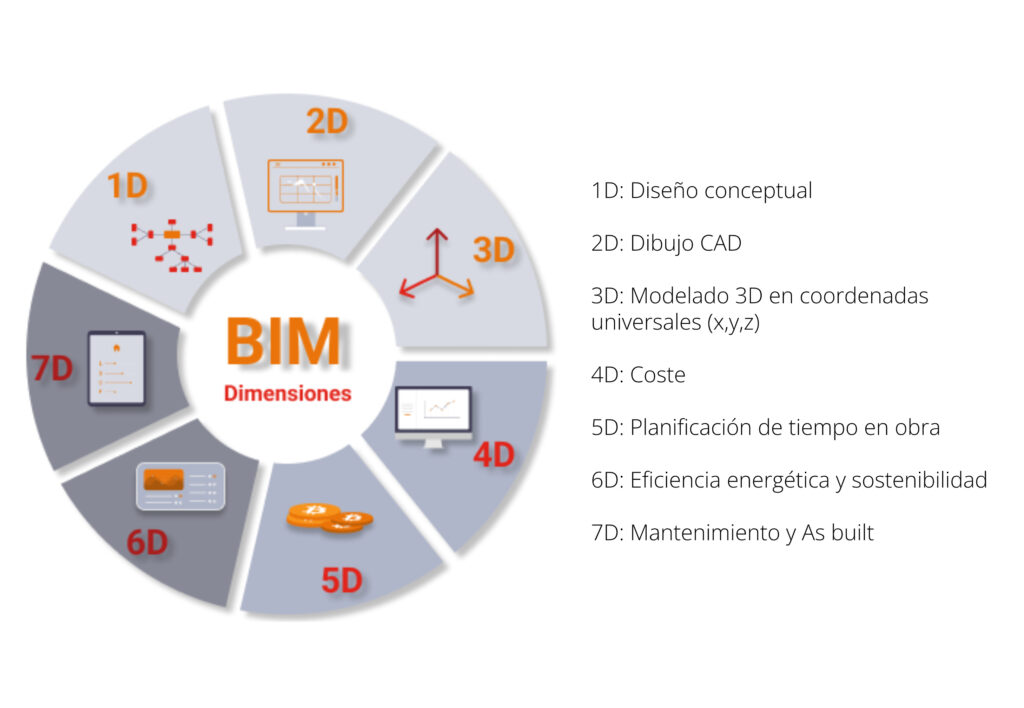

This data management and control are possible thanks to the various layers that can be incorporated into a digital model. These layers are known as the 7 dimensions of a BIM model.

⇢ What do Tecnitex BIM objects bring to our clients?

To optimally develop a project using BIM methodology, it is necessary for manufacturers to provide BIM objects as a digital representation of the product we are going to manufacture, with sufficient information. This way, the object functions as a specification element and makes work easier for engineers, architects, and specifiers.

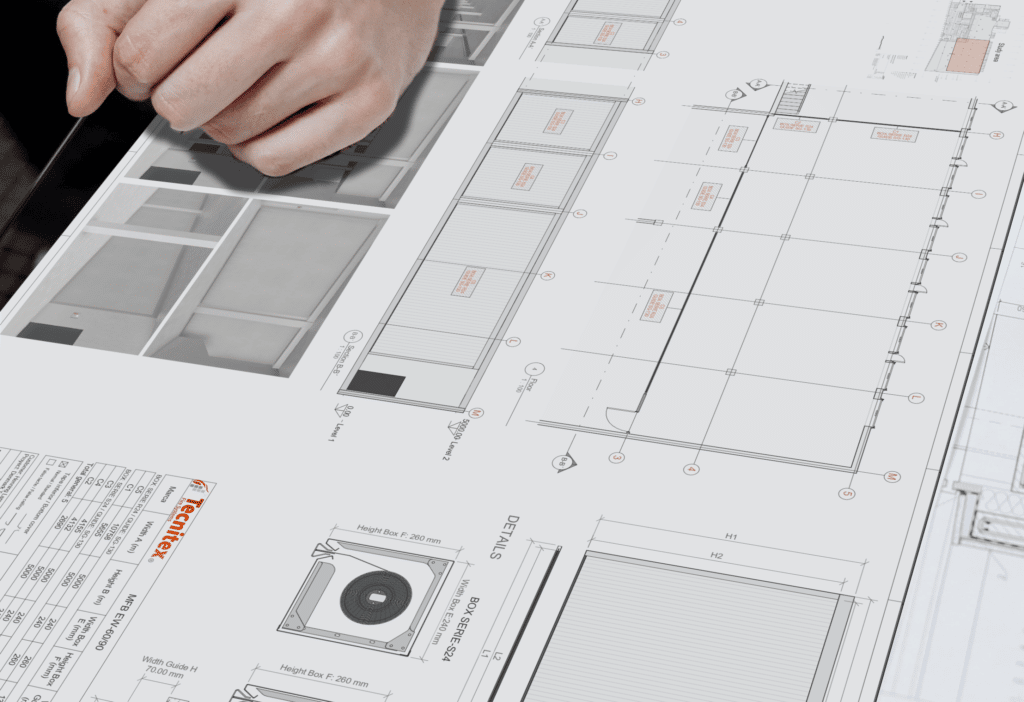

◌ During the design and specification phase

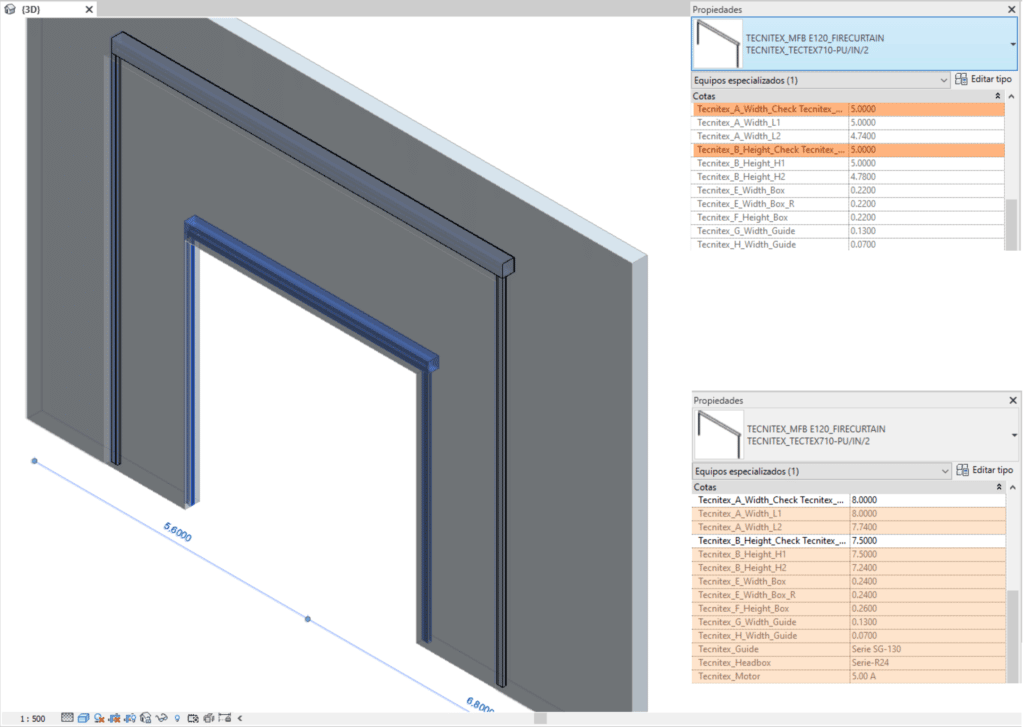

Through Tecnitex BIM objects, the client has access to more information than what appears on technical sheets or catalogs. As interactive elements, programmed with our data and certifications, the designer only needs to enter the general measurements (L1/H1), and the element itself will return the type of box and guides with their dimensions.

Additionally, it allows the user to configure the type of installation for guides and boxes (attached or recessed), the type of bottom cover or the type of trim, lower the curtain to detect clashes with projected elements such as furniture or building components, or select how to control the curtains (all with one control or with multiple controls), among others.

With this tool, we offer our clients the possibility to improve their requests, as it allows them to send us more specific product information they need for their project, streamlining the process and creating more accurate budgets, helping them calculate the total costs of the project.

◌ During the construction phase

Data management in BIM models during the various project phases allows coordination of manufacturing tasks, delivery on-site, and installation, incorporating this data into the construction planning once the order has been placed and the delivery deadline confirmed.

◌ During asset maintenance

In our sector, this phase is possibly the most important of the entire process. The maintenance of fire curtains or smoke curtains is key to improving their lifespan and ensuring proper functioning in case activation is necessary. Therefore, it is essential to know the installation date of the curtain to understand its warranty and the date of required maintenance to ensure it is performed properly and on time.

Additionally, during this phase, the BIM object allows the building operator to know the characteristics of the curtain in case it needs to be replaced, without the need for prior studies, and allows us, as manufacturers, to have all the information to offer new product alternatives.

⇢ Conclusions

Tecnitex BIM objects enable us to develop a data model that facilitates the management of information about our products in a project. They allow for simpler coordination between the various agents involved in the project, streamline workflows, reduce time and costs, make interference detection easier, generate simpler and more accessible workflows, and facilitate asset maintenance, improving the lifespan of our products.

María López

BIM Architect at Tecnitex Fire Systems